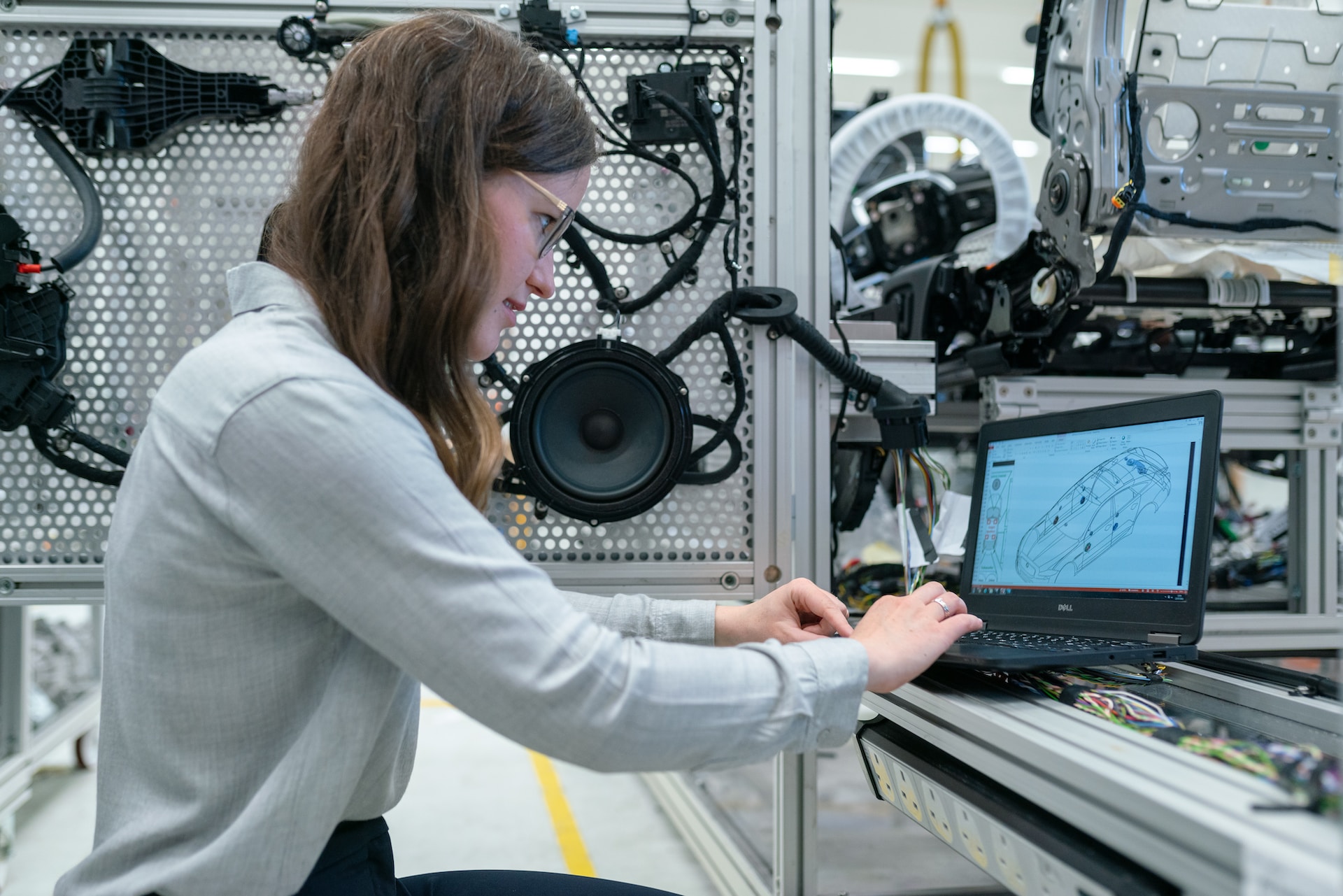

Custom manufacturing software development

We understand the key role technology plays in optimizing manufacturing processes, improving productivity and remaining competitive in today’s dynamic marketplace. Our team of experts is committed to creating innovative solutions that address the unique challenges faced by manufacturing companies.

From streamlining manufacturing processes to improving supply chain management, we use the latest technologies to enhance manufacturing operations. Whether you’re a small manufacturer or an established industrial player, we are here to drive your success to new levels. Let us unlock the full potential of your manufacturing business with our customized and scalable software services.

What are manufacturing industries?

Manufacturing industries are sectors of the economy in which products are made from raw materials or components. They involve the use of machinery, tools and workers to transform these materials into finished goods that people use or buy. Examples of manufacturing industries include automobile manufacturers, electronics companies and clothing manufacturers. These industries are important because they create jobs, contribute to the economy and produce the things we use in our daily lives.

What is custom software for manufacturing?

Custom manufacturing software is software specifically designed to meet the unique needs of manufacturing companies. It helps improve and upgrade various processes related to production, inventory management, quality control and supply chain.

Unlike off-the-shelf software, custom software is adjusted to the specific requirements of each manufacturing company, making it more efficient and effective in increasing overall efficiency and productivity.

Our custom manufacturing software development services

At NEATsoft, we have a wide range of custom manufacturing services to offer, designed to revolutionize and optimize manufacturing processes while ensuring smooth operations in all aspects of your business. Take a look at some of the most important custom manufacturing solutions we provide, each of which has been specifically designed to meet unique requirements and improve production efficiency:

Production planning & reporting solution

Our tailor-made software solutions are specifically developed to facilitate effective production planning and reporting in real time. With this comprehensive tool at your side, you can effortlessly track progress, analyze data and make informed, data-driven decisions that maximize productivity and deliver positive results.

Custom Enterprise Resource Planning (ERP) software

We specialize in developing custom ERP software that effectively integrates every aspect of manufacturing operations. From enhanced inventory management to highly organized financial processes, our ERP solutions integrate business functions for increased efficiency and seamless communication.

Order & inventory management software

With our bespoke order and inventory management software, maintaining optimal stock levels and automating order processing becomes effortless. You can confidently navigate your supply chain, ensuring timely deliveries and keeping your operations running smoothly.

Production and workflow monitoring and automation apps

Embrace the power of real-time monitoring and workflow automation with our tailor-made apps. These tools empower you to keep a close eye on production processes, identify areas for improvement, and reduce errors, thereby boosting overall productivity.

Integration into manufacturing software solutions

Seamless integration of custom software into your existing production systems is a proof of our commitment for improving data flow and ensuring the highest operational efficiency. Our specialized integration services make it easy to create a consistent and harmonious technology environment for your business.

Equipment maintenance application development

Our custom equipment maintenance applications are designed to help you schedule and manage equipment maintenance tasks with ease. By minimizing downtime and optimizing your equipment’s performance, you can boost productivity and extend the lifespan of your valuable assets.

Developing condition monitoring software

Harness the power of predictive maintenance with our customized condition monitoring software solutions. These innovative tools enable you to anticipate maintenance needs, proactively prevent failures and ultimately reduce downtime, leading to significant cost savings and increased productivity.

Manufacturing ERP software

Our custom ERP manufacturing software is a comprehensive solution that expertly streamlines and optimizes every step of the manufacturing process. From tracking raw materials to overseeing the finished product, our ERP system provides a consistent and efficient manufacturing ecosystem.

Environmental health and safety (EHS) management systems

We take employee safety and environmental responsibility seriously. Our EHS management systems are meticulously developed to ensure compliance with safety regulations, protect employees and reduce environmental risks, creating a safe and sustainable work environment.

Benefits of custom manufacturing software development for manufacturing industry

Custom manufacturing software development offers customized solutions that optimize manufacturing processes, increase efficiency and boost productivity in the manufacturing industry. Targeting specific business needs and challenges, custom software provides seamless integration with existing systems, real-time data visibility and streamlined operations. This leads to increased efficiency, better usage of resources and improved decision-making, ultimately providing a competitive advantage in a dynamic manufacturing landscape.

Increased efficiency

Custom manufacturing software development offers tailored solutions that streamline and automate various manufacturing processes. By eliminating manual tasks and optimizing workflows, companies can significantly increase operational efficiency, reduce production time, and enhance overall productivity.

Enhanced visibility and control

Custom software allows manufacturing companies to have real-time visibility into their entire production process. With detailed reporting and analytics, businesses gain valuable insights that enable better decision-making, resource allocation, and performance monitoring. This heightened visibility leads to improved control over production operations, minimizing errors and maximizing output.

Cost savings

Investing in custom manufacturing software development can lead to notable cost savings in the long run. By eliminating inefficiencies, reducing material waste and optimizing resource usage, companies can lower production costs and increase profitability. Custom software also helps improve inventory management, avoiding excess inventory and associated maintenance costs.

Scalability and adaptability

Off-the-shelf software can have limitations when it comes to meeting specific production needs or adapting to future growth. On the other hand, custom software is designed to be scalable and adaptable, allowing companies to easily modify and expand the system as their business requirements evolve. This flexibility ensures that the software will continue to effectively meet the company’s needs over time, making it a valuable long-term investment.